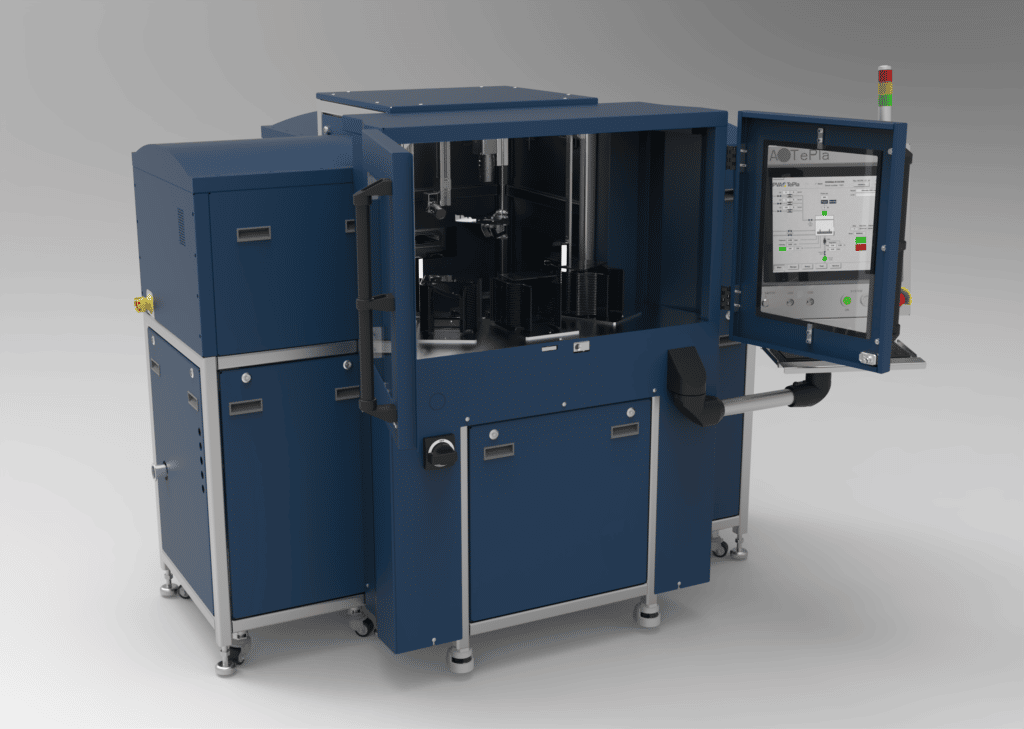

The Automatic Single Wafer Asher GIGAfab LED is designed to serve fabrication of opto-electronics, MEMS and power devices. It is equipped with a unique microwave plasma source for high uniformity, providing highly productive processing across a wide temperature range.

The modular platform can be configured for 100, 150 or 200 mm wafer size with multiple cassette stations and up to three process chamber modules. Each process chamber features a gravity wafer chuck with lift pins for loading and unloading. It is thermoelectrically controlled from 65°C to 250°C. Wafers are loaded and unloaded by an atmospheric robot with dual arm configuration for highest throughput. A cooling plate allows cool down of the wafers prior to re-loading into the plastic cassettes. The chamber lid is easy to open for maintenance access (clam shell opening).

Wafer throughput: varying from 30-180 wafer/hour, depending on process and number of process chamber modules. Temperature range for stripping: 100-250°C Uniformity: +/- 7.5% across 200 mm for Descum

Aluminum

2 gas channels included, 2 optional

MKS Baratron capacitance manometer

Proprietary microwave source

2.45 GHz, maximum power 1000 W

Optical emission EPD, plasma

verification

PC-based controller, with graphical

user interface

QNX real time platform

USB, RS232 interface

Light tower R/Y/G/buzzer

CE-certified, Semi S2/S8 compliant

Down-stream control valve

1-2 bar (15–30 psi), 1/4” Swagelok

6 mm Festo QS, 4-6 bar, (60-90 psi)

4 mm Festo QS, <20kPa, 50 l/min