In 2022, PVA TePla America (PTA), in Corona California, became fully operational as a contract service house for diffusion bonding joining. Client interest has grown steadily.

To spread adoption, the Diffusion Bonding Group at PTA welcomes inquires seeking R&D or commercial contracting.

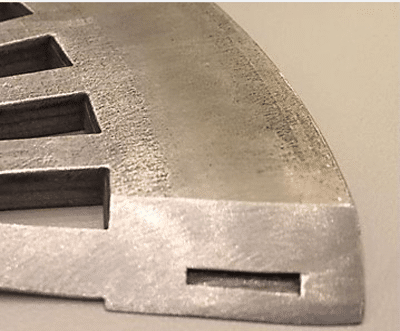

The usefulness of diffusion bonding is maximum with a combination of discreet materials selection, tight geometrical tolerances, and high-purity service assembly performance. Its successful implementation is a collaboration of meticulous mechanical design, and highly controlled materials processing.

Parties developing avant-garde technologies related to the follow areas may best be suited to benefit:

The typical first step may be to initiate a limited-in-scope development program.

During the course of such action, the client is generally able to assess if the processing needs and manufacturer volume warrant the process to be aggregated internally to the corporation. This would require a capital outlay for a furnace. Currently, there is a long lead-time for delivery globally.

If you have a new advanced design, or are struggling with manufacturing nuances, diffusion bonding may be the ONLY joining method that leverages the brightest ideas of your engineering team. Please reach us at sales@pvateplaamerica.com .

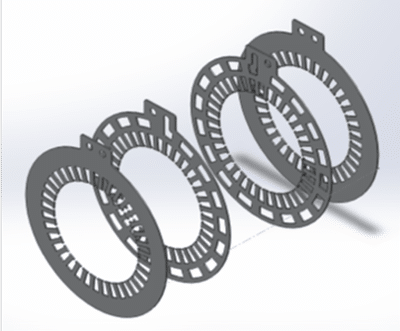

Heat Exchangers

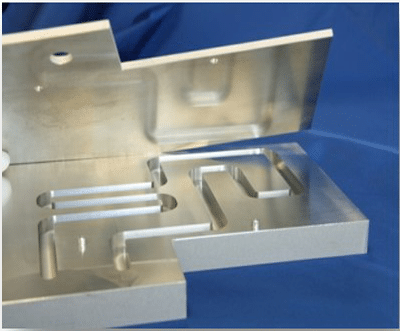

Cooling Plates

Manifolds

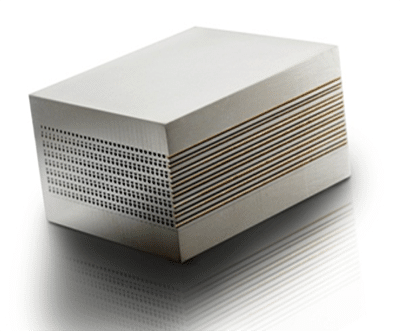

Multilayer Heat Sinks

Multilayer Bonding

The video shows the principle and function of the diffusion bonding process and demonstrates the advantages of our furnace. Diffusion bonding allows metal parts to be joined without the use of filler materials. The patented process that PVA TePla has developed can combine to similar or dismilar metals to create a joint-free connection.

The advantages at a glance:

Diffusion Bonding Printable PDF download 1.800.527.5667 for more information.

Business: 951-371-2500

Sales: 800-527-5667

Fax: 951-346-3232

U.S. Contact

U.S. Sales

Tom Palamides

Phone: 951-741-7365

Email: thomasp@pvateplaamerica.com

PVA TePla AG

Im Westpark 10 -12, 35435

Wettenberg, Germany

Tel: +49 (641) 686900