Vinyl Ester

How to improve adhesion to vinyl ester?

Silicone

How to improve adhesion to silicone?

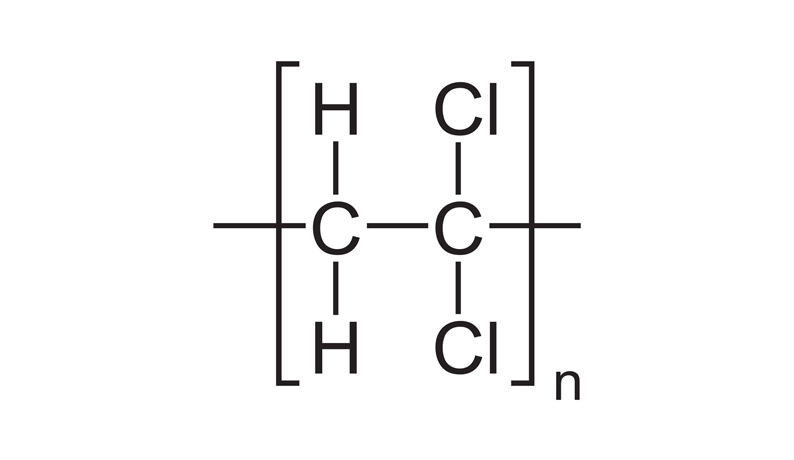

Polyvinylidene Chloride (PVDC)

How to improve adhesion to polyvinylidene chloride?

Polyvinyl Chloride (PVC)

How to improve adhesion to polyvinyl chloride?

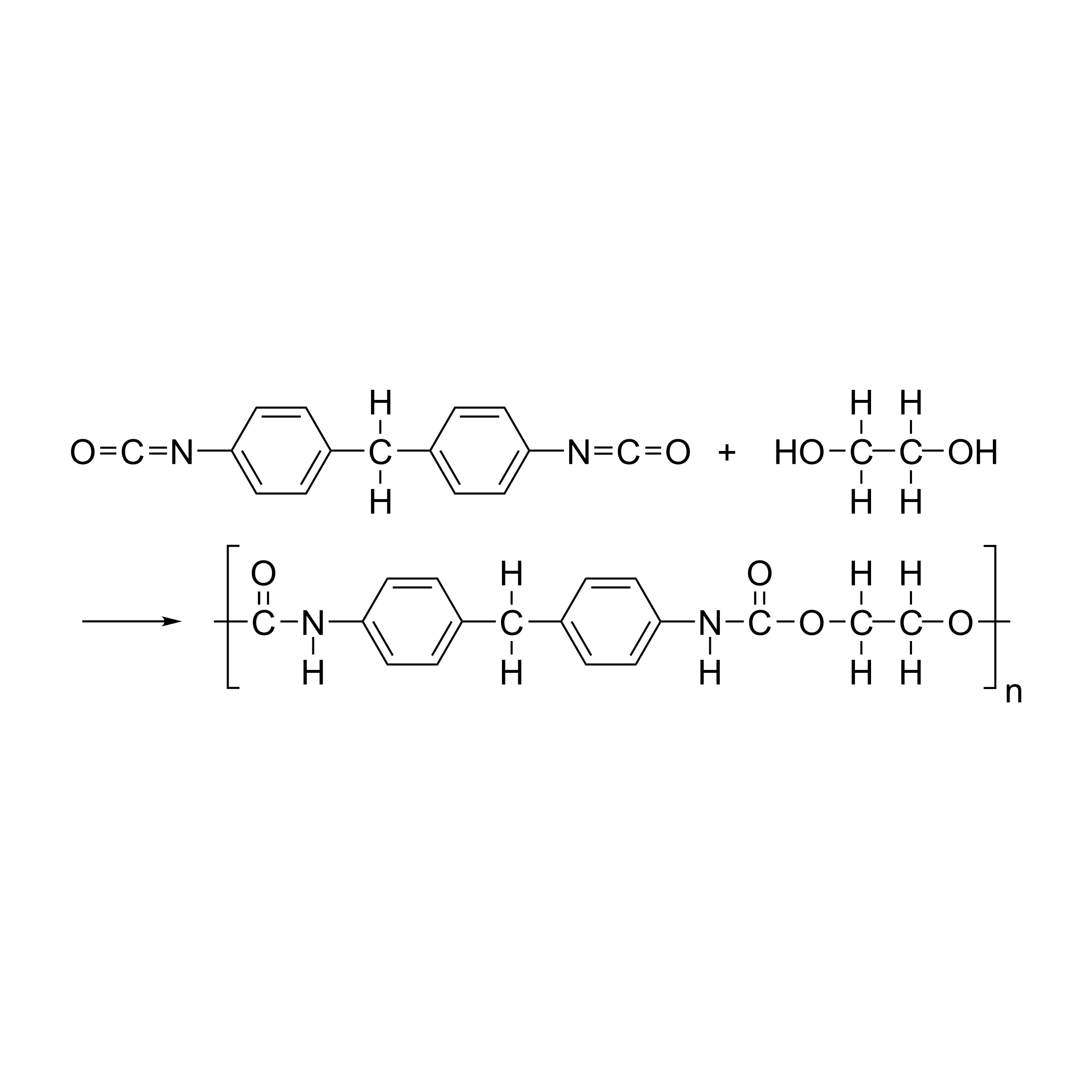

Polyurethane

How to improve adhesion to polyurethane?

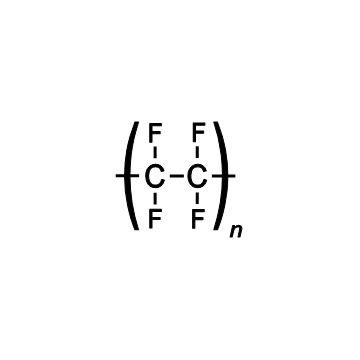

Polytetrafluoroethylene (Teflon®)

How to improve adhesion to polytetrafluoroethylene?

Polysulfone

How to improve adhesion to polysulfone?

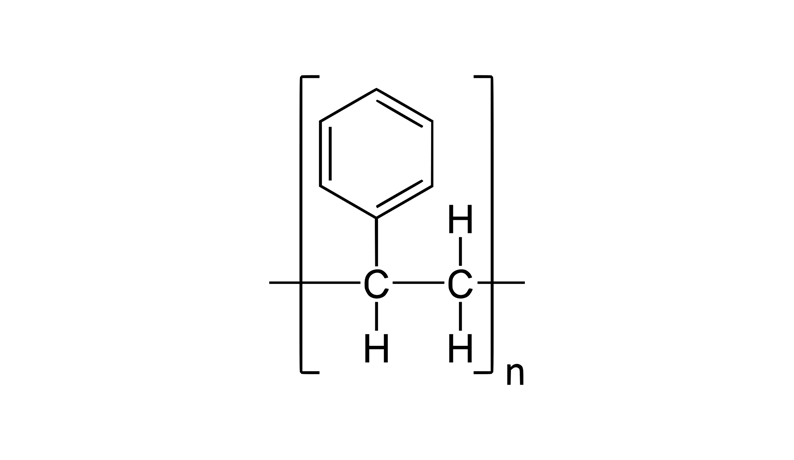

Polystyrene

How to improve adhesion to polystyrene?

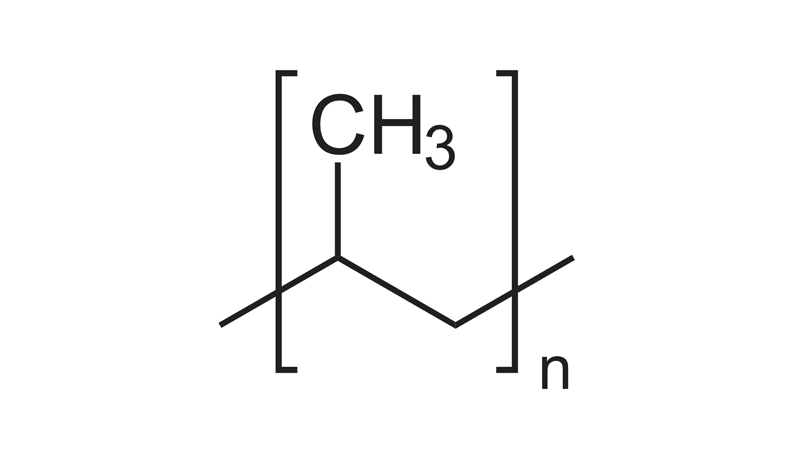

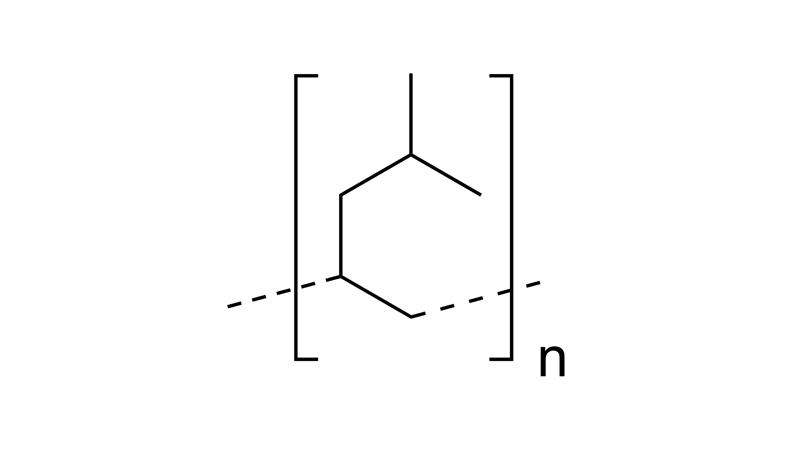

Polypropylene

How to improve adhesion to polypropylene?

Polyphthalamide

How to improve adhesion to polyphthalamide?

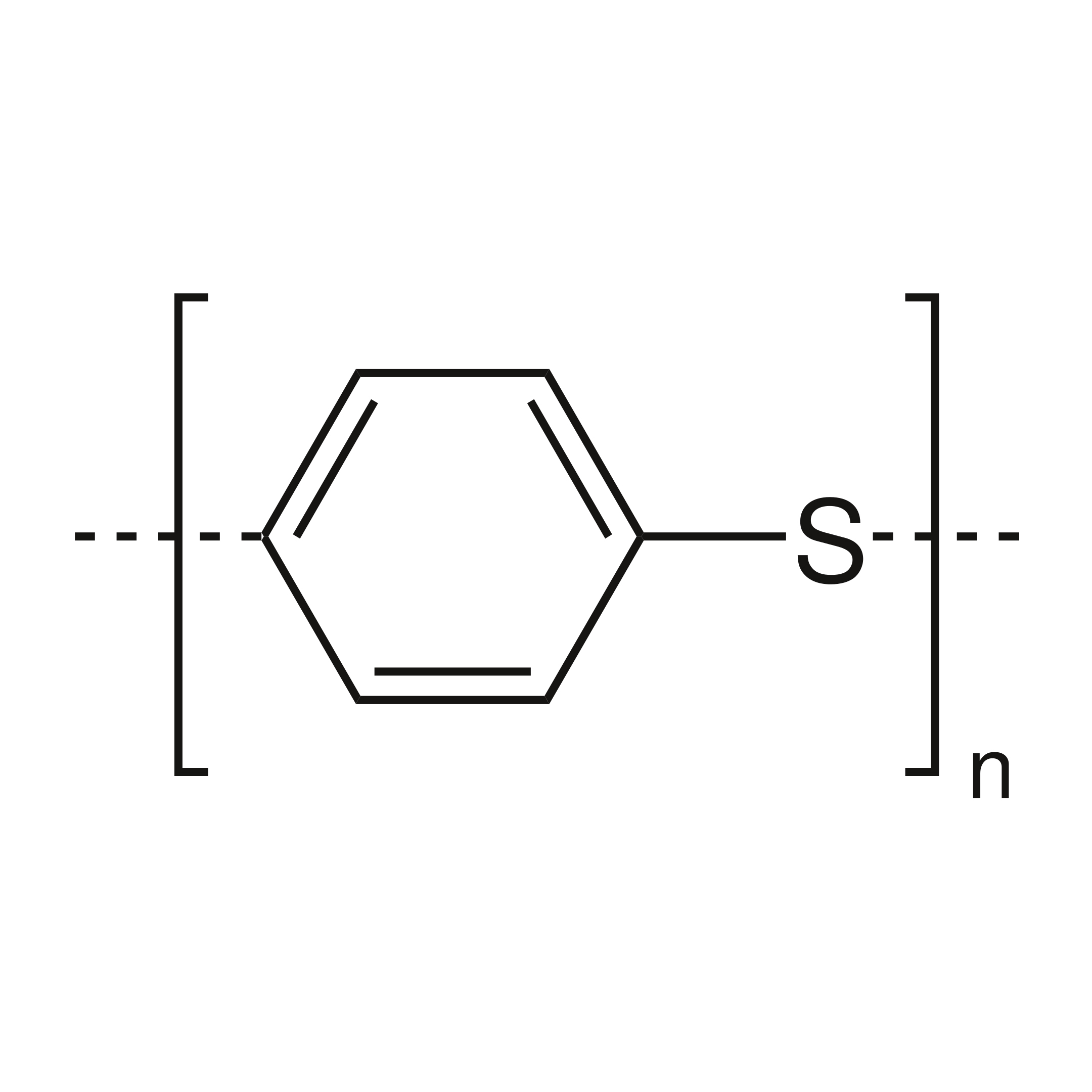

Polyphenylene Sulfide

How to improve adhesion to polyphenylene sulfide?

Polymethylpentene

How to improve adhesion to polymethylpentene?

Polyimide (PMR®-15)

How to improve adhesion to polyimide?

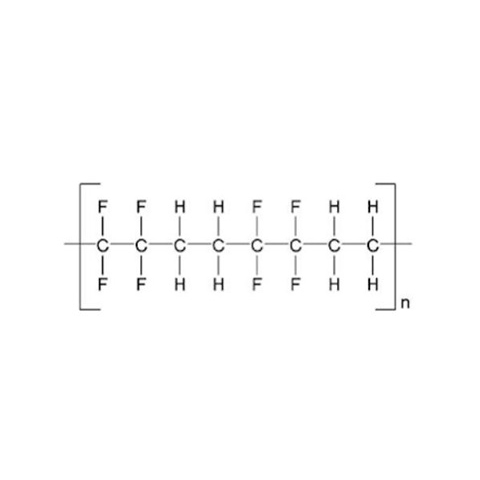

Polyethylenetetrafluoroethylene (Tefzel®)

How to improve adhesion to Tefzel®

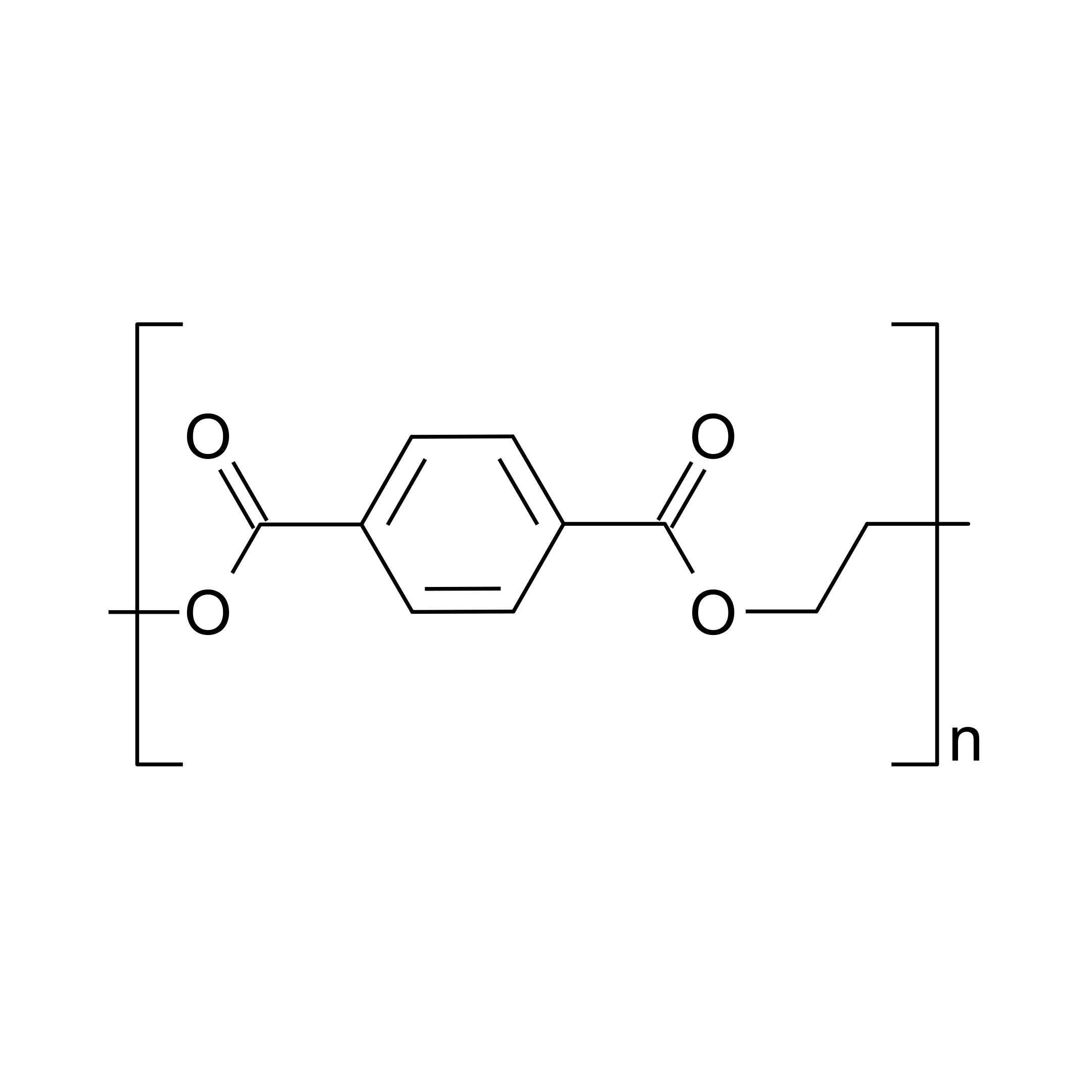

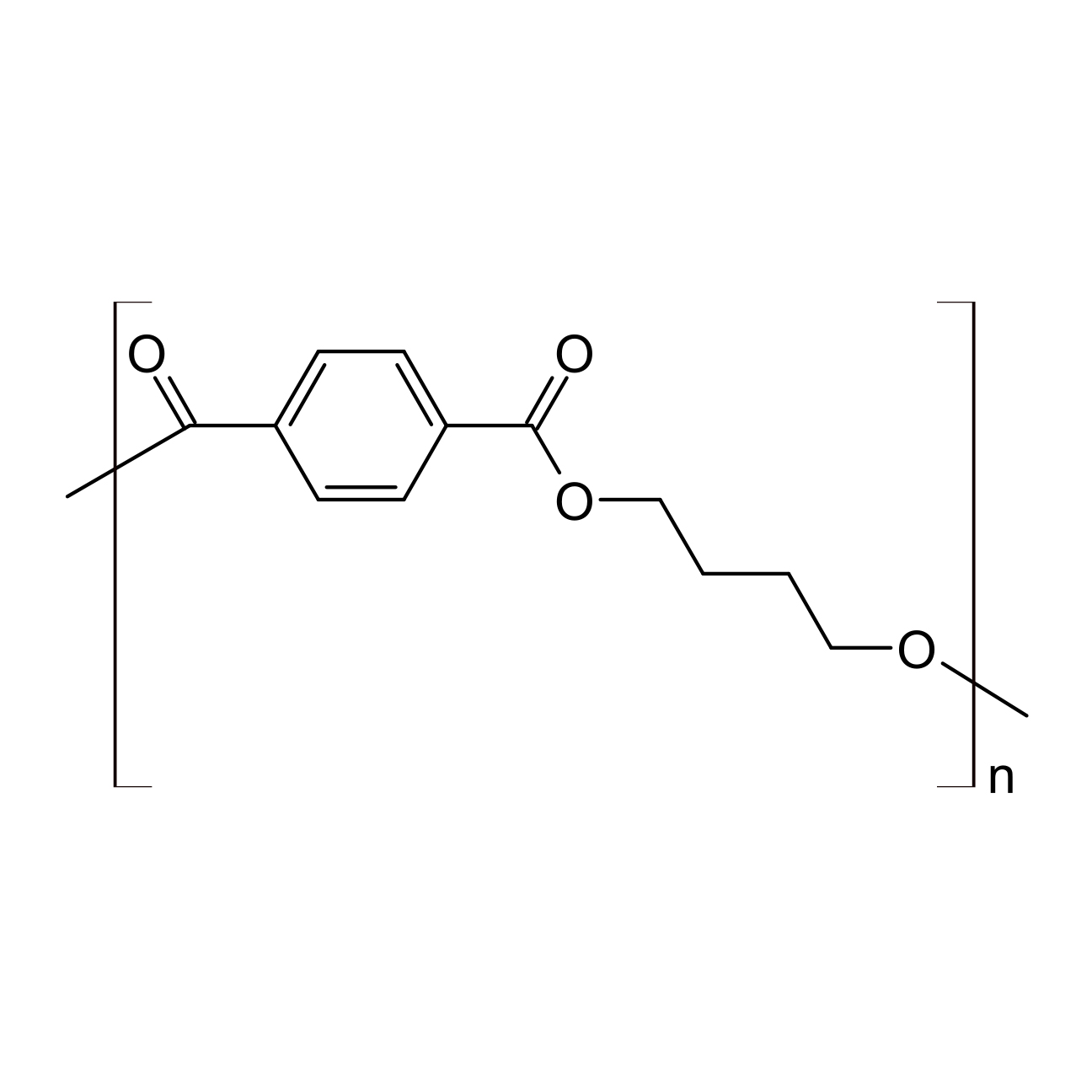

Polyethylene Terephthalate

How to improve adhesion to polyethylene terephthalate?

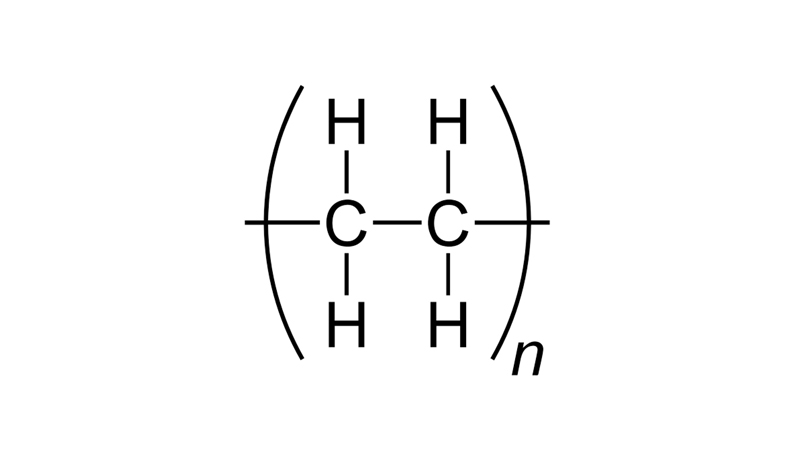

Polyethylene Low Density (PELD)

How to improve adhesion to PELD?

Polyethylene high density (PEHD)

How to improve adhesion to polyethylene?

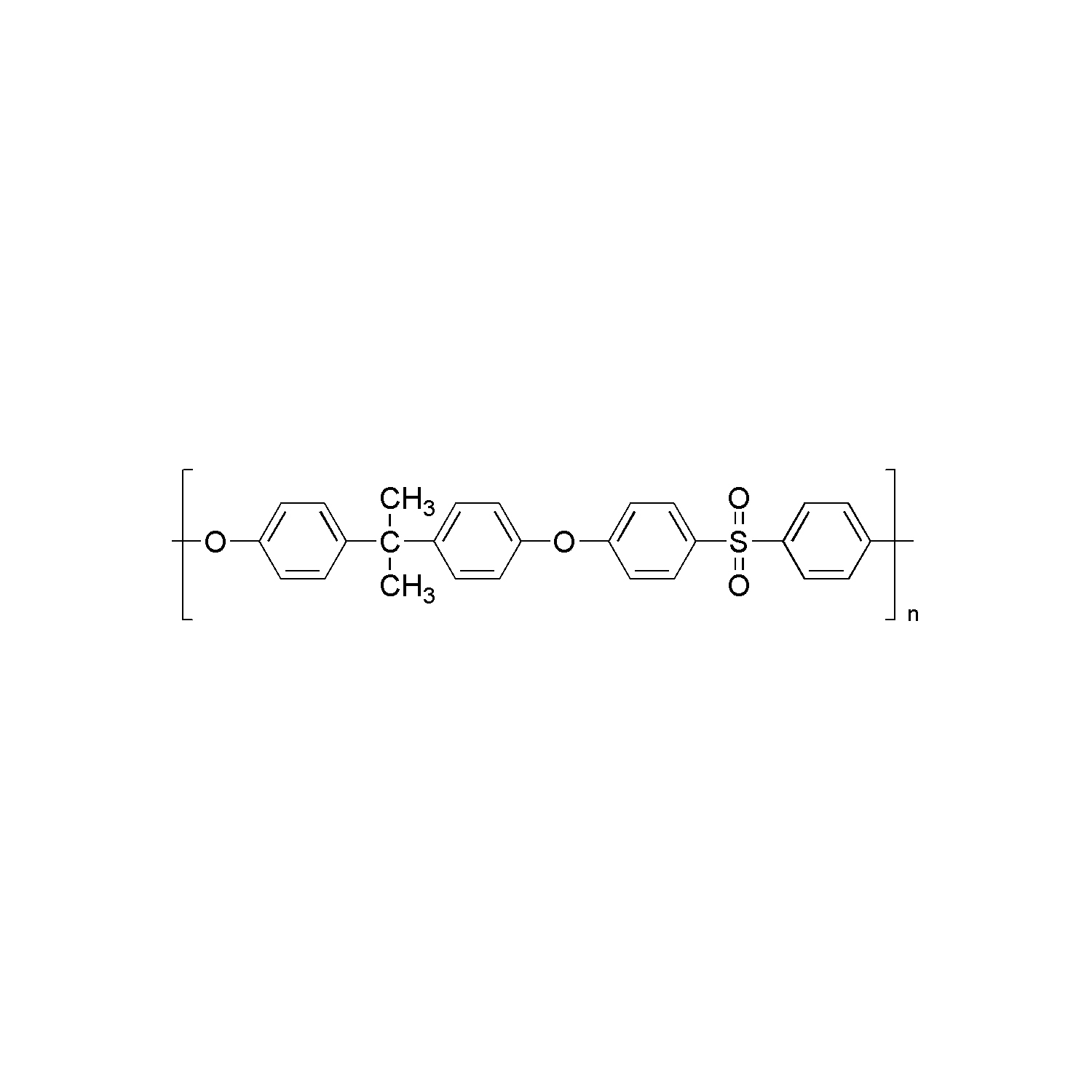

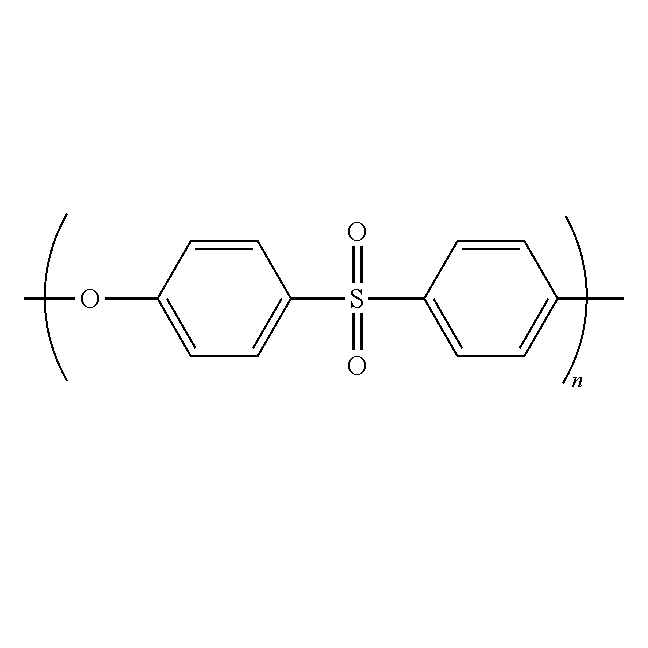

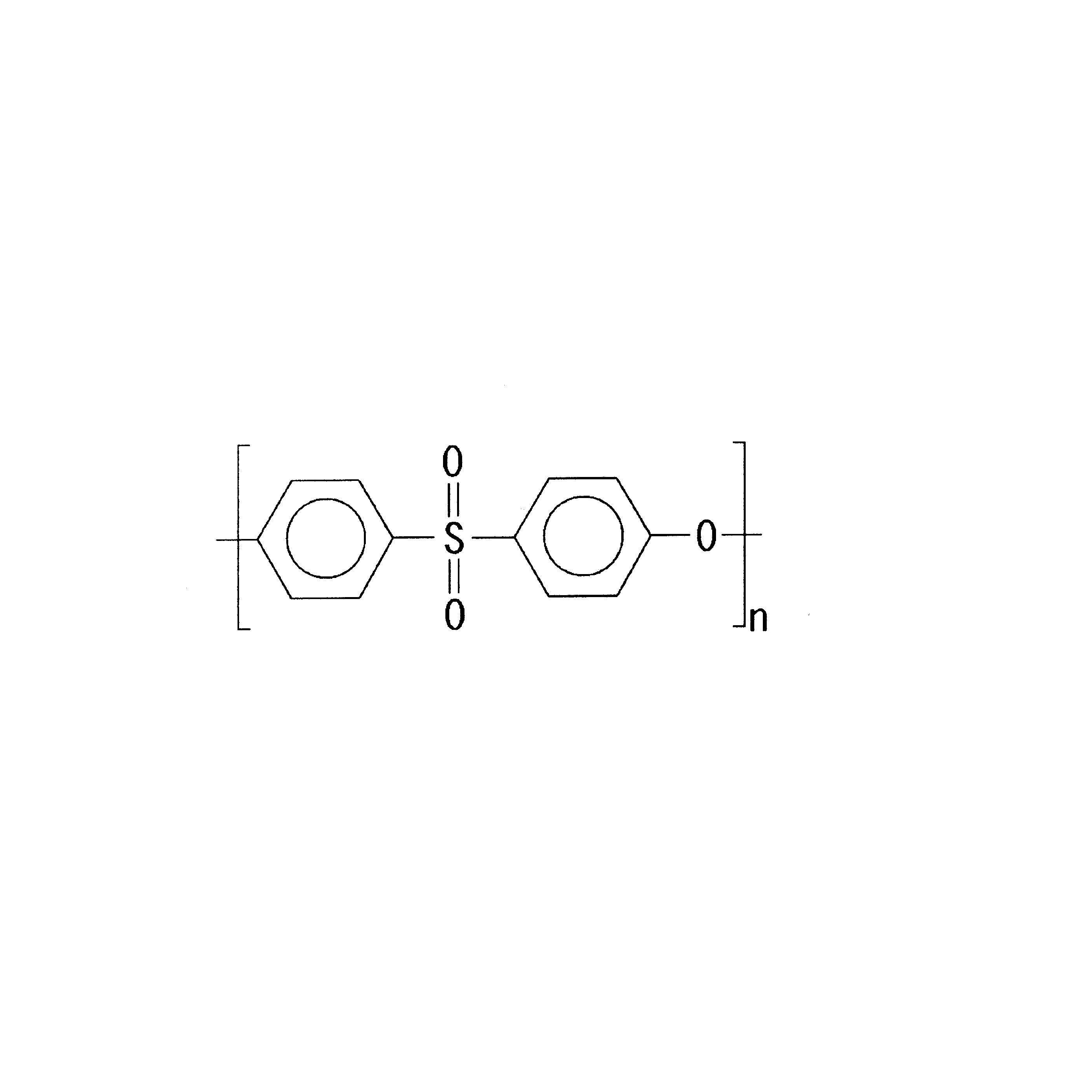

Polyethersulfone

How to improve adhesion to polyethersulfone?

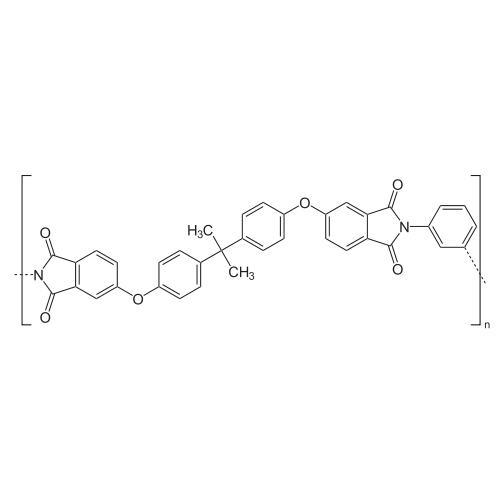

Polyetherimide

How to improve adhesion to polyetherimide?

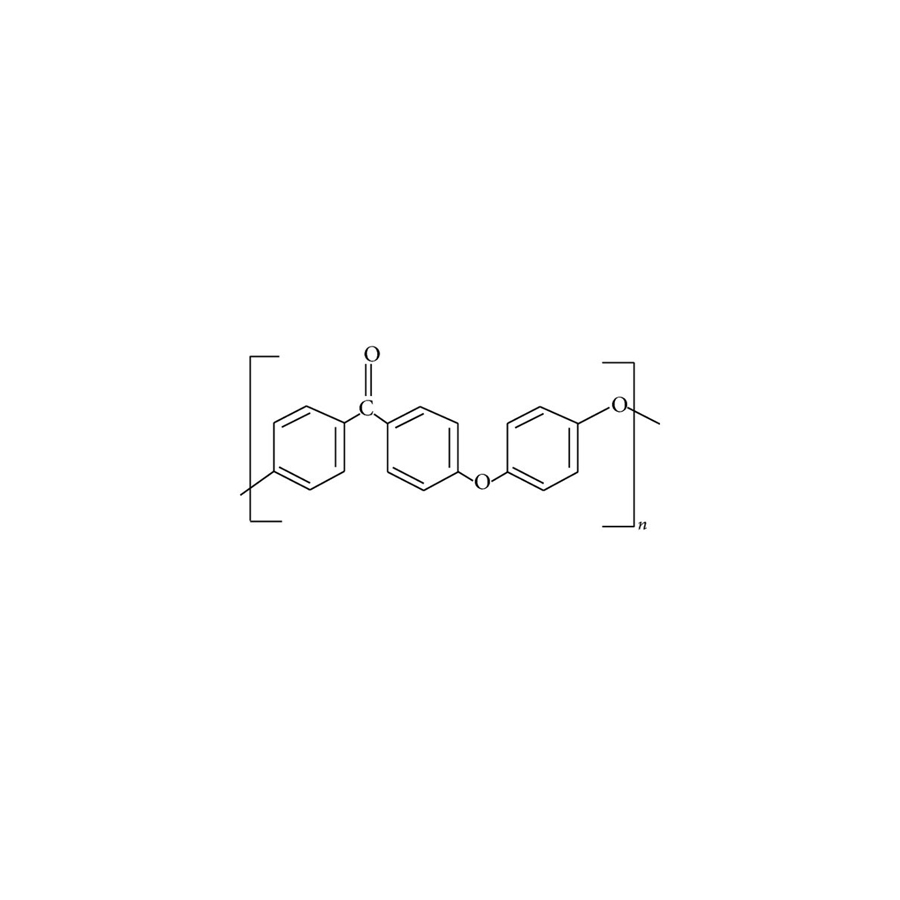

Polyetheretherketone (PEEK)

How to improve adhesion to polyetheretherketone?

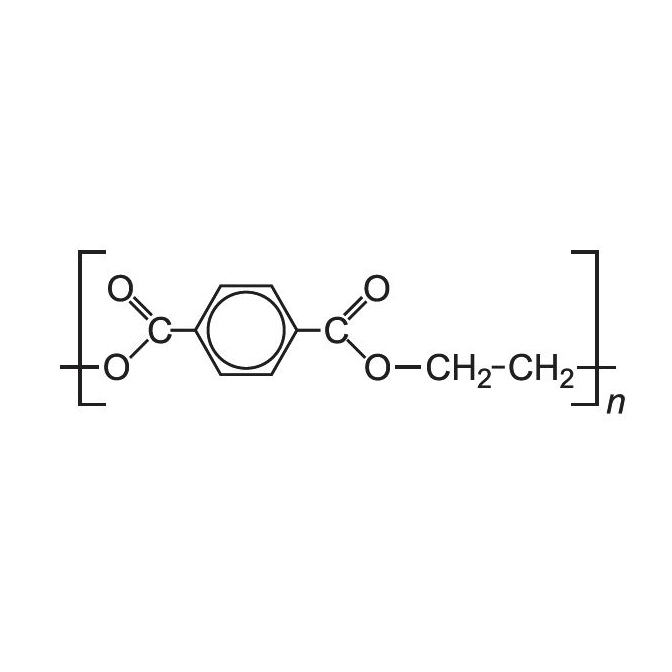

Polyester

How to improve adhesion to polyester?

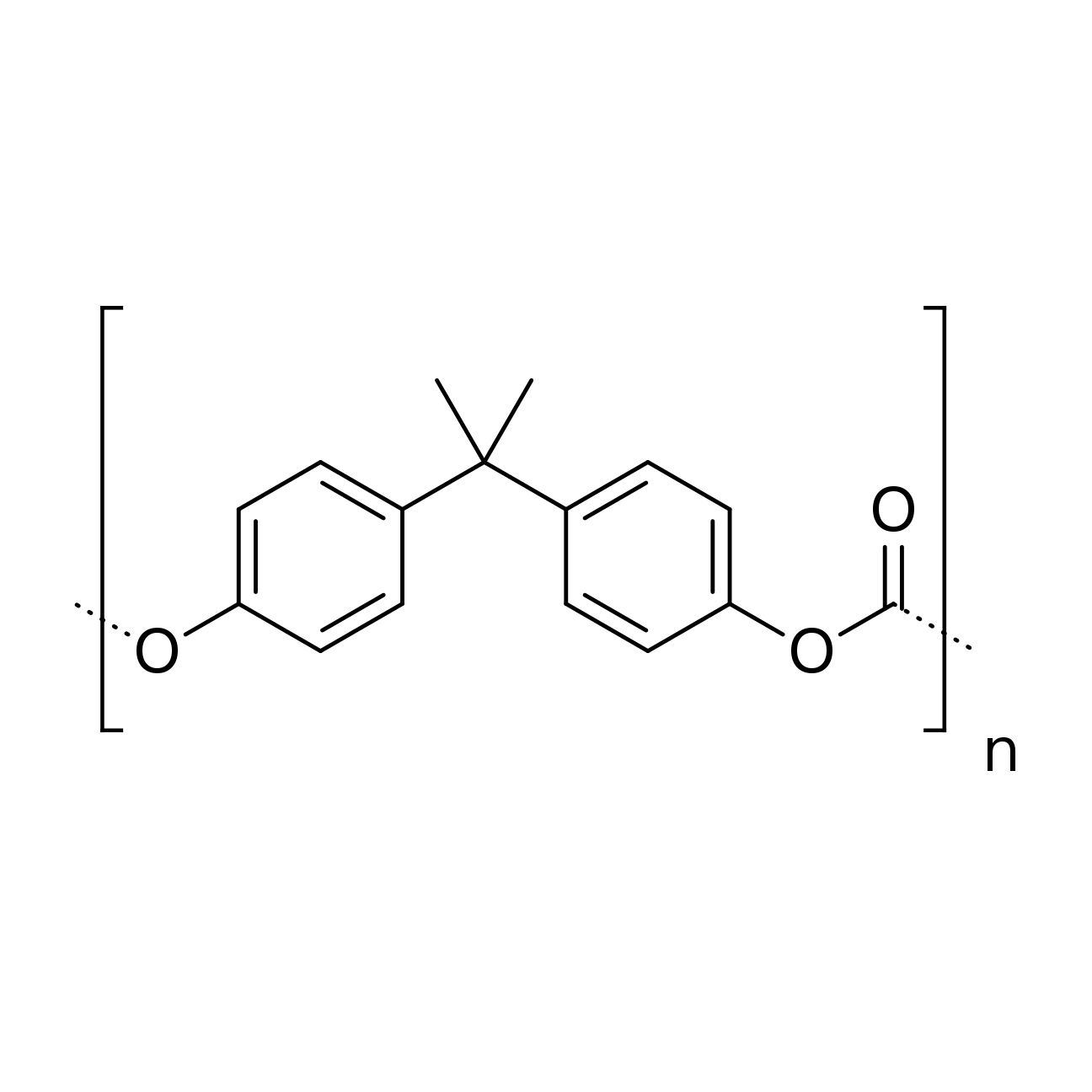

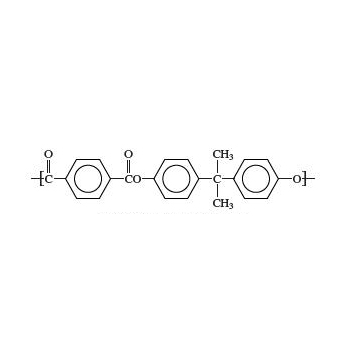

Polycarbonate (Lexan®)

How to improve adhesion to polycarbonate?

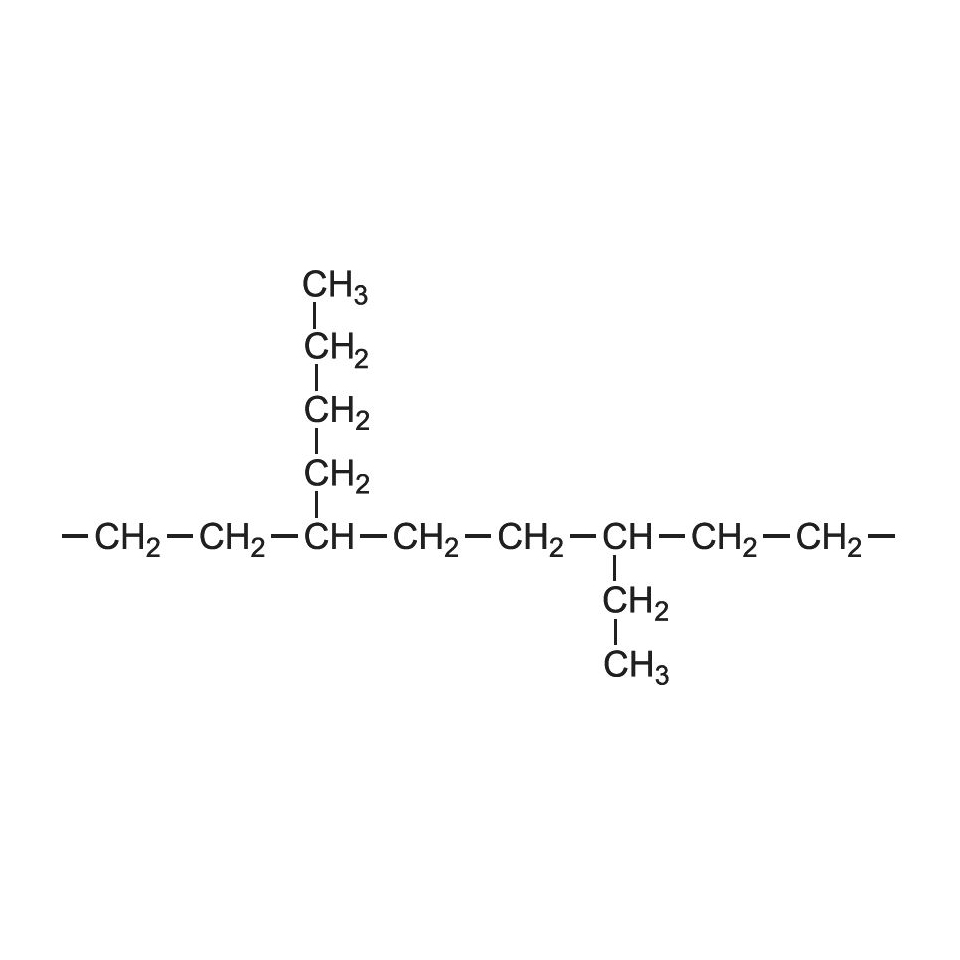

Polybutylene

How to improve adhesion to polybutylene?

Polyarylsulfone

How to improve adhesion to polyarylsulfone?

Polyarylate

How to improve adhesion to polyarylate?

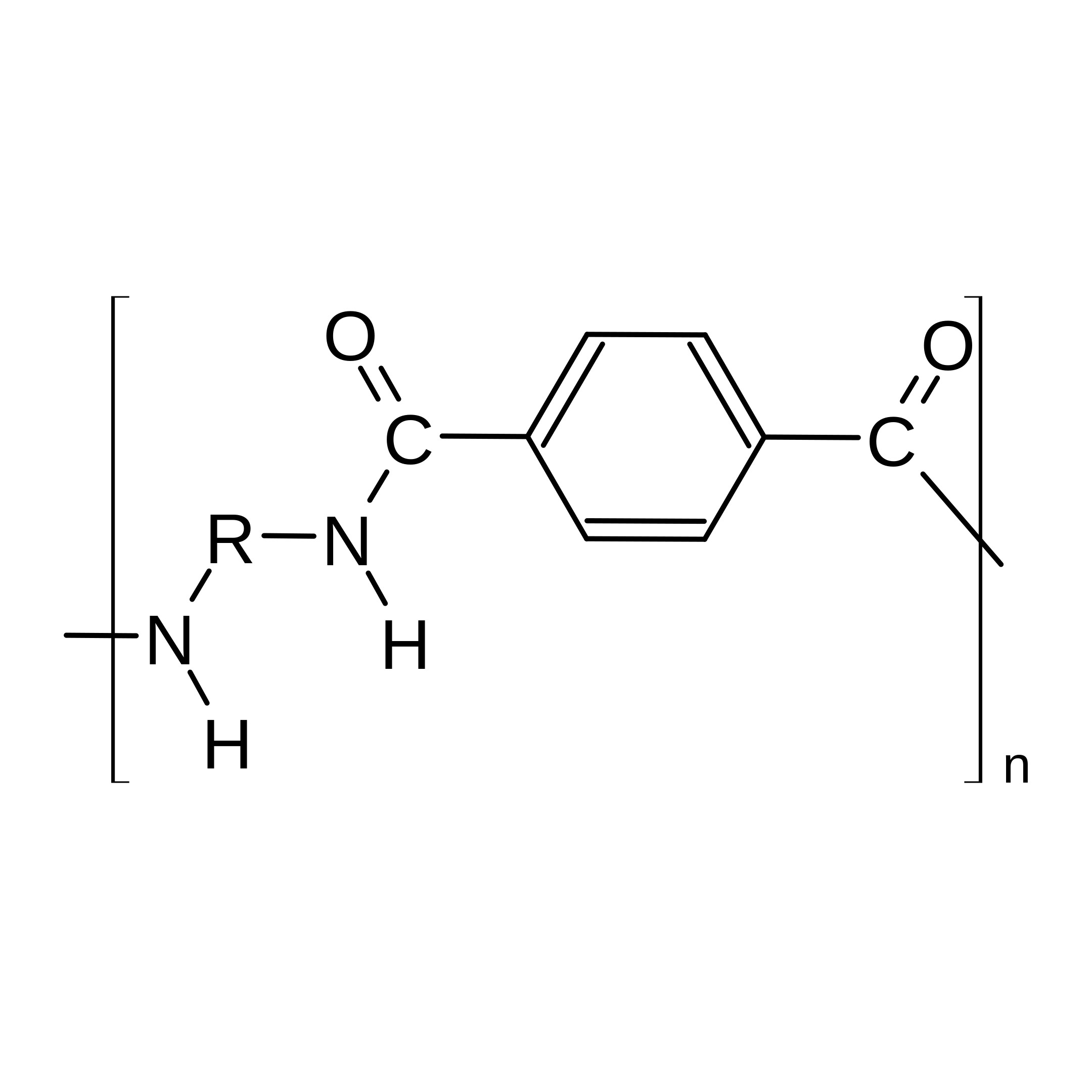

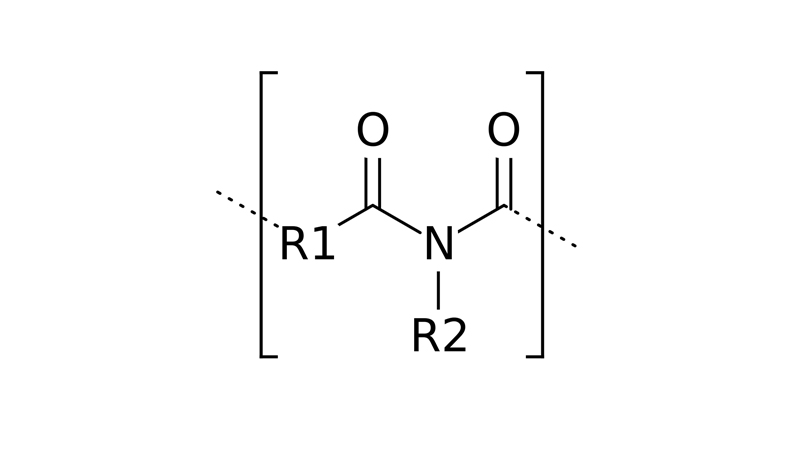

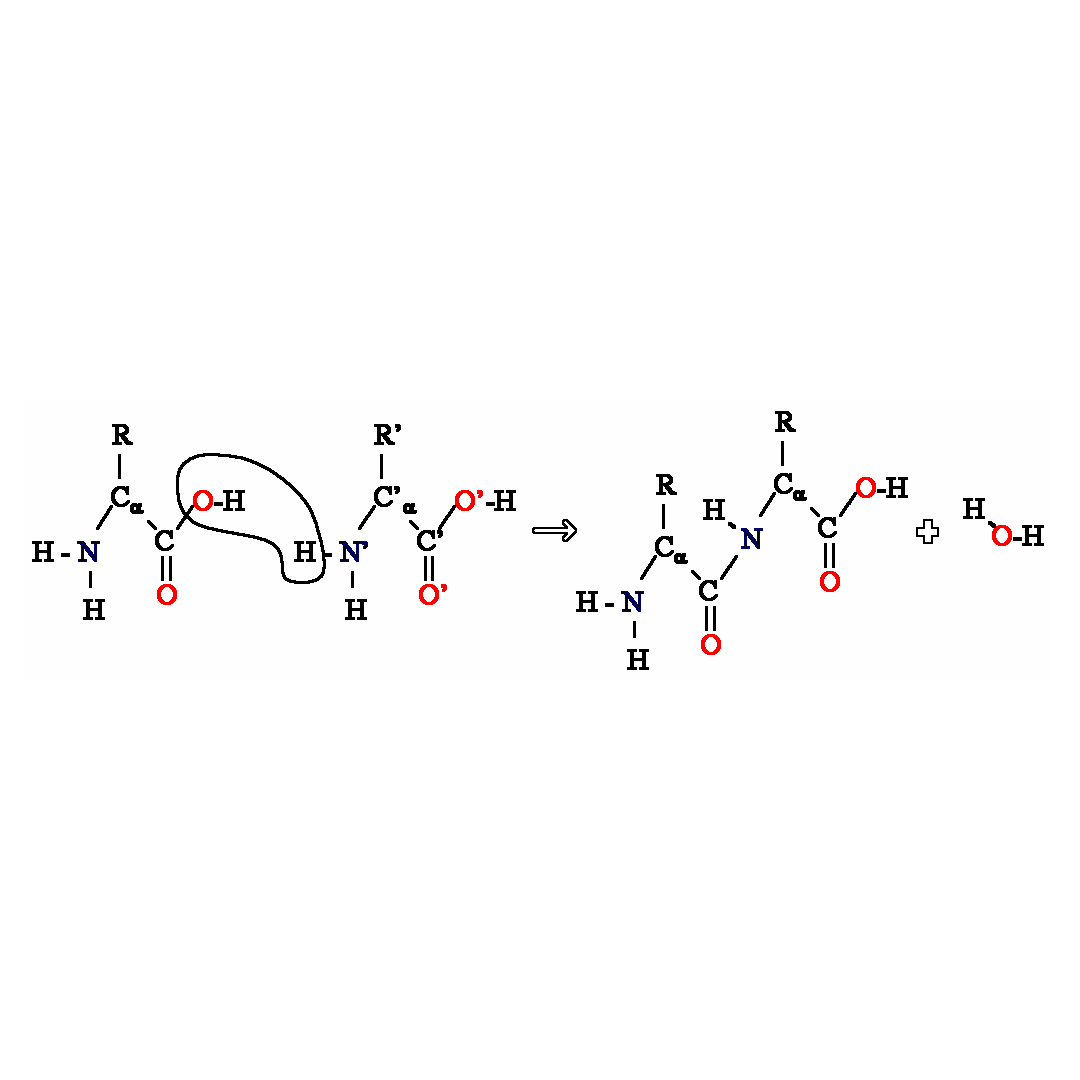

Polyamide (Nylon)

How to improve adhesion to nylon?

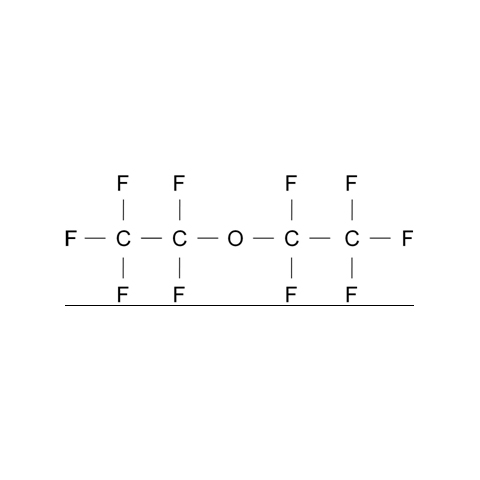

Perfluoropolyether (PFPE)

How to improve adhesion to perfluoropolyether?

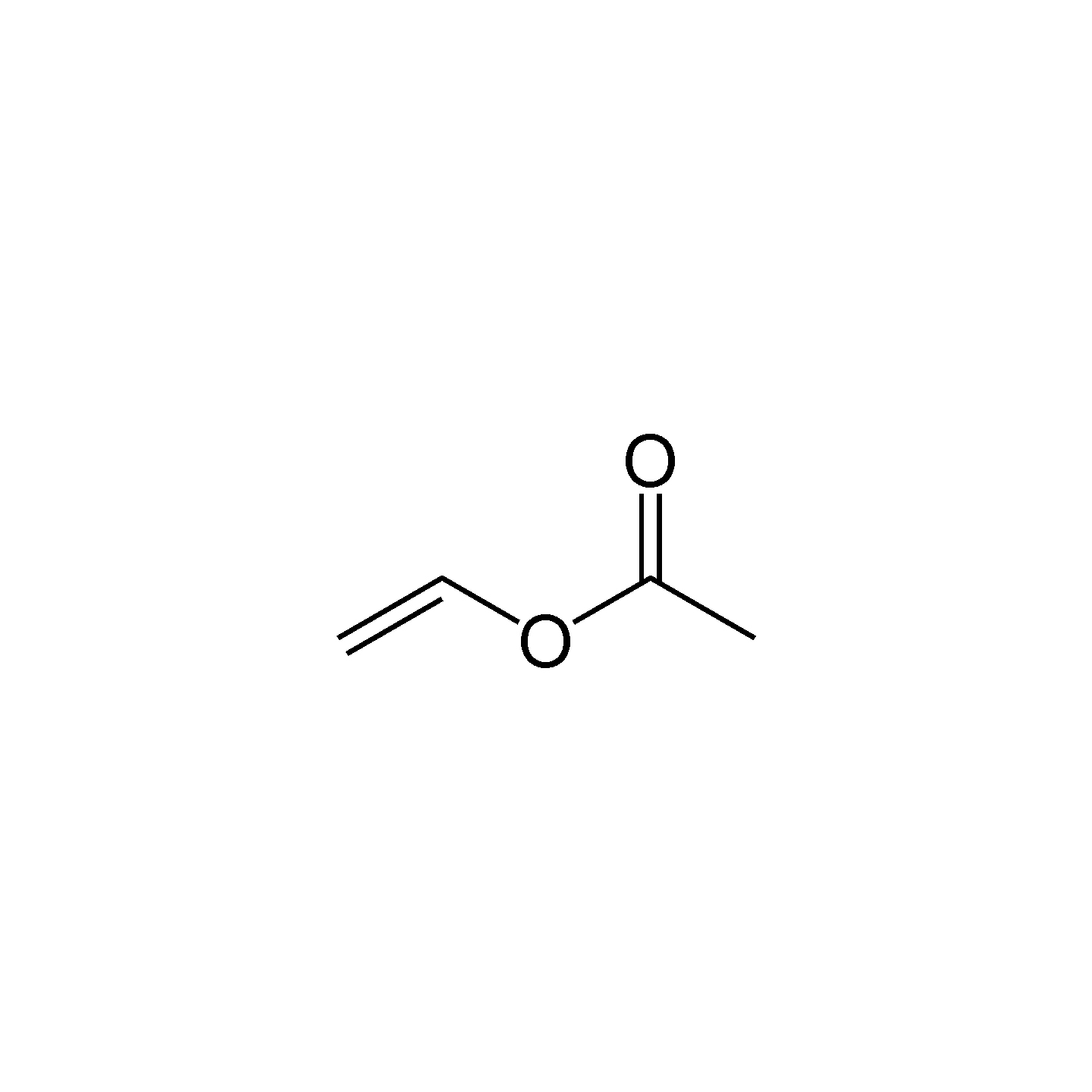

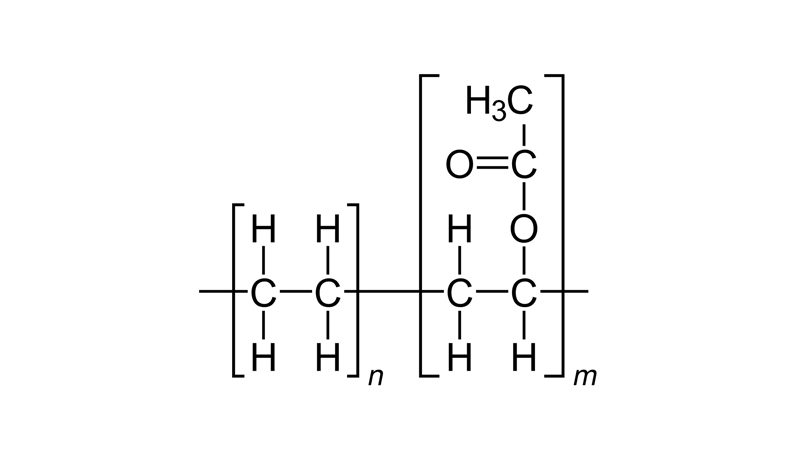

Ethylene Vinyl Acetate

How to improve adhesion to ethylene vinyl acetate?

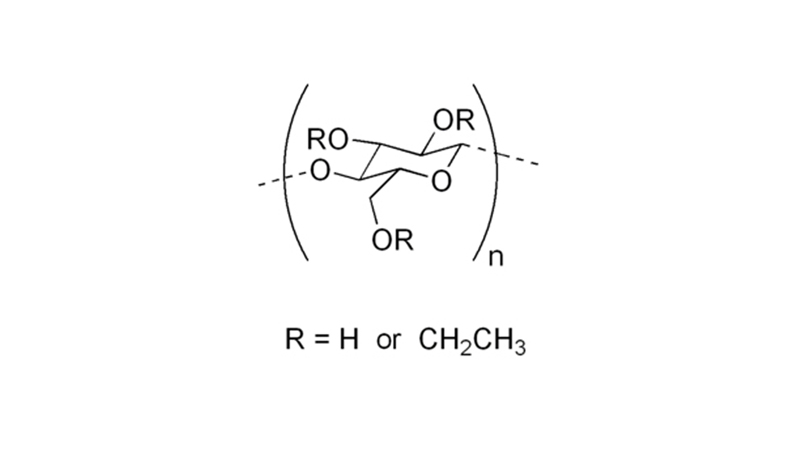

Ethyl Cellulose

How to improve adhesion to ethyl cellulose?

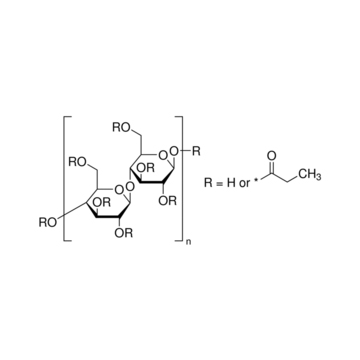

Cellulose Propionate

How to improve adhesion to cellulose propionate?

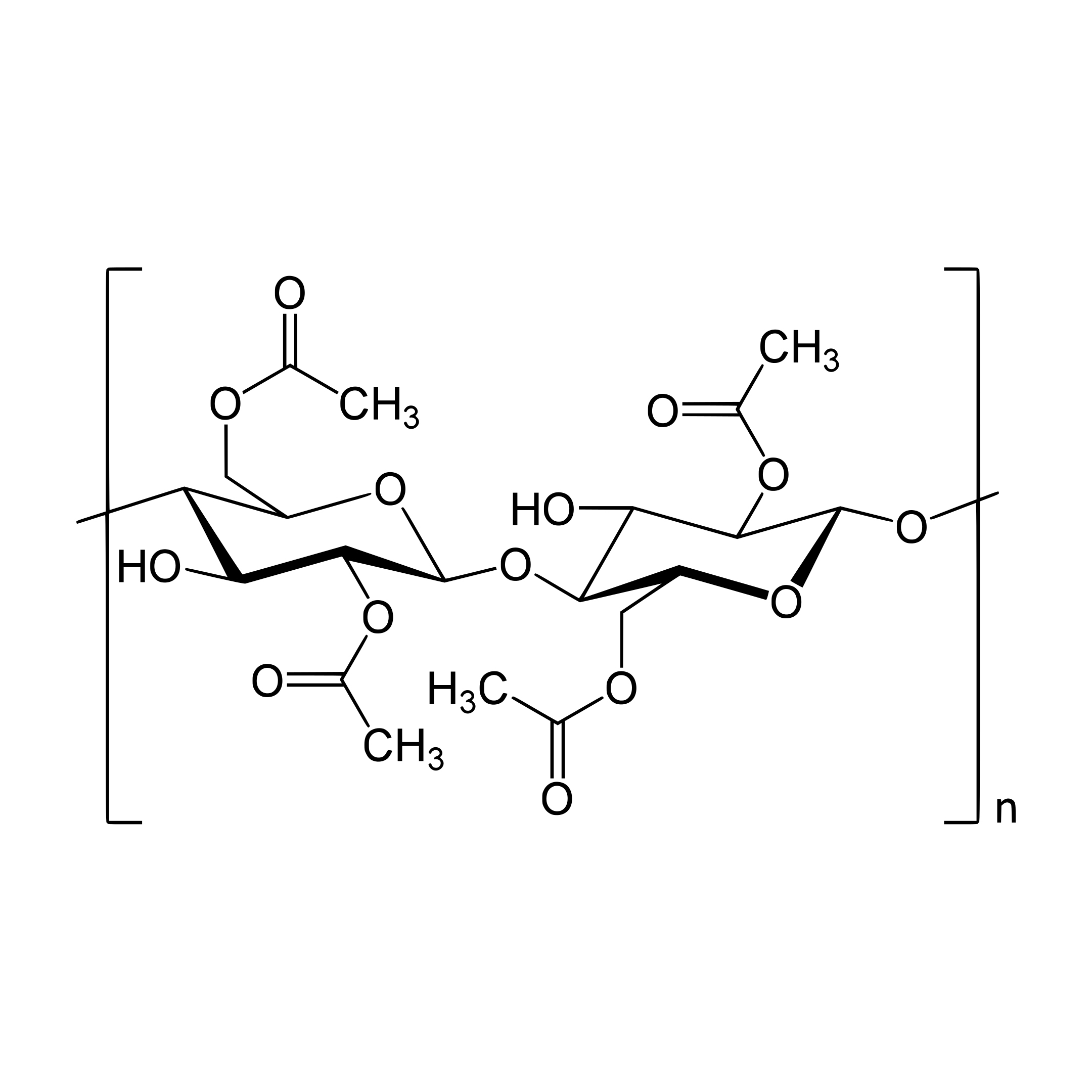

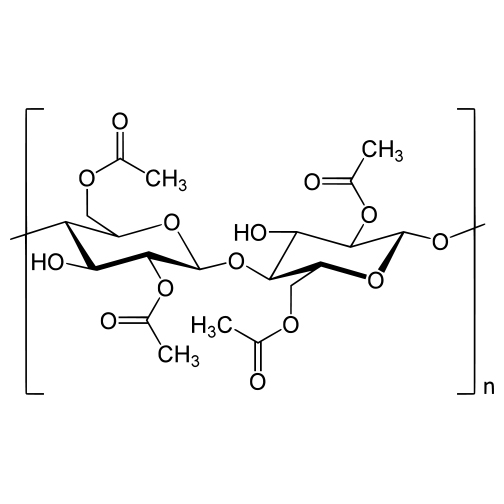

Cellulose Acetate

How to improve adhesion to cellulose acetate?

Cellulose Acetate Butyrate

How to improve adhesion to cellulose acetate butyrate?

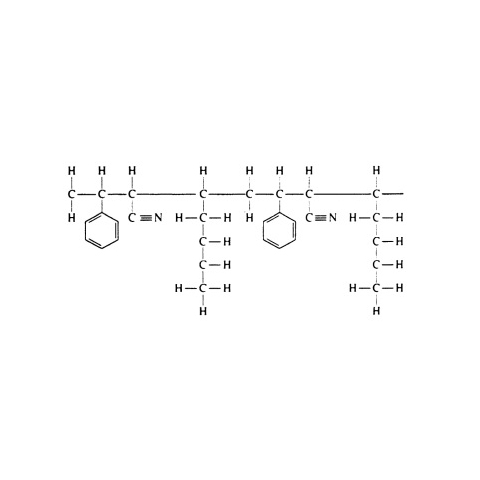

Acrylonitrile Butadiene Styrene (ABS)

Acrylonitrile Butadiene Styrene (ABS)

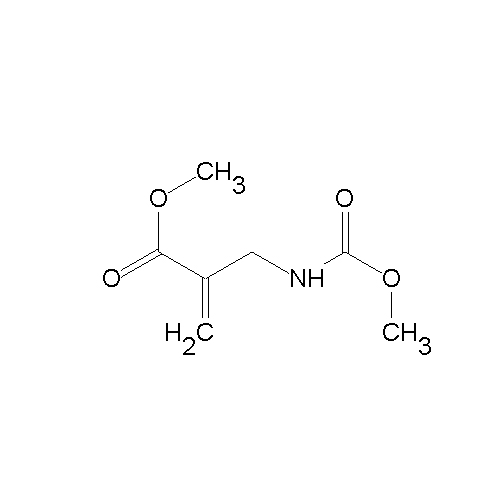

Acrylic

How to improve adhesion to Acrylic?

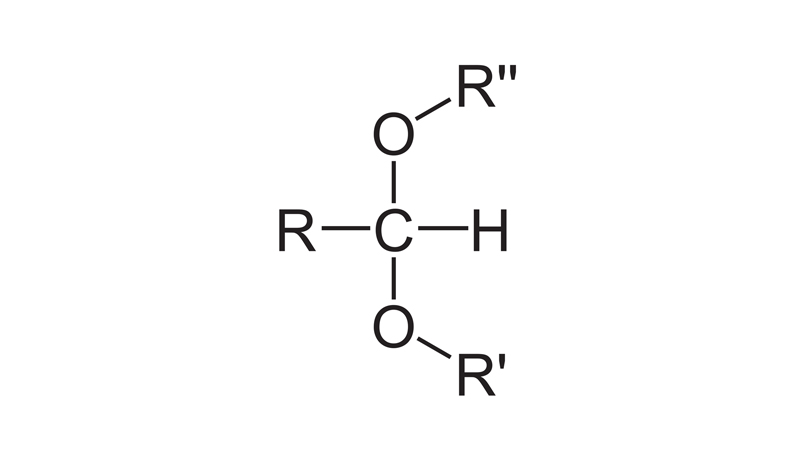

Acetal

How to improve adhesion to acetal?