PVA TePla MPS Munich Metrology GmbH, a wholly owned subsidiary of PVA TePla, is a leading edge supplier of VPD Systems, Vapor Phase Decomposition equipment with two decades of VPD experience with both equipment and applications. In 2012 Munich Metrology was acquired by PVA-TePla to expand their Semiconductor Group metrology capabilities. Munich Metrology products are manufactured in a clean room environment by PVA-TePla in our factory Jena Germany.

Munich Metrology offers the most advanced, fully integrated, VPD Measurement System available today. The WSMS includes a leading edge VPD Systems, Vapor Phase Decomposition, sample collection system with a state-of-the-art chemical delivery system that automatically provides all the chemicals for VPD and all the chemicals required for the calibration of the integrated ICP-MS analysis system. It is a complete measurement system under the control of one computer that accepts remote commands and provides measurement results in real time through a SECS/GEM factory automation interface. The advantages of the WSMS include:

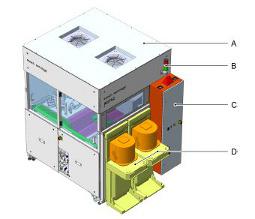

WSPS systems include the processing modules, a robot, cassette stations and fixed load interface stations for FOUPS in a system enclosure that provides filtered clean air, utilities and power to the individual modules. WSPS software provides complete system operation capability and data collection including custom Recipe Set-Up, Job Definition, Job Execution, Management of Wafer Priority and Remote Monitoring and Operation.

Munich Metrology also offers a variety of VPD, Vapor Phase Decomposition, Modules and Systems for sample collection with a wide range of options and applications. Modules provide the VPD functions of etching the native oxide and scanning the wafer surface with a droplet to collect a sample for ICP-MS analysis. There is also a module for drying the sample prior to TXRF analysis or heating the sample to drive off unwanted chemical compounds prior to ICP-MS analysis. VPD Modules are available for stand-alone operation or for integration into an automated WSPS, Wafer Surface Preparation Systems.

Both modules and systems can be selected with a variety of application options:

PVA-TePla America

Munich Metrology US Sales

251 Corporate Terrace

Corona, CA 92879

tkupec@pvateplaamerica.com