Teflon Activation

Teflon® ( Polytetrafluoroethylene ) , with its very low dielectric constant, is an excellent material to ensure fast signal propagation and superb isolation properties.

Stamper Conditioning

Poor polycarbonate release properties after stamping can scratch and snag the data bits during detachment of the replicate from the…

Stamper cleaning

With the advent of Blu-ray formats, optical disc technology celebrates its third generation of high density data storage media. As…

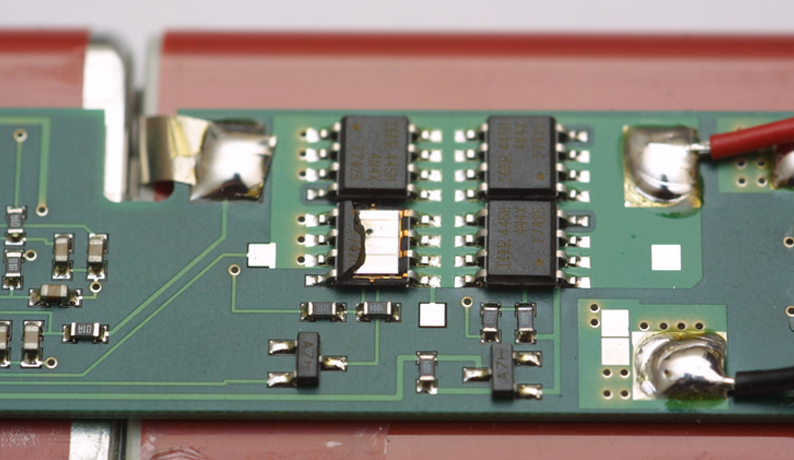

Potting

Plasma activation prior to potting ensures a good hermetic seal, reduces current leakage and provides stronger physical bonding to the device. The protection of electronic or electrical devices

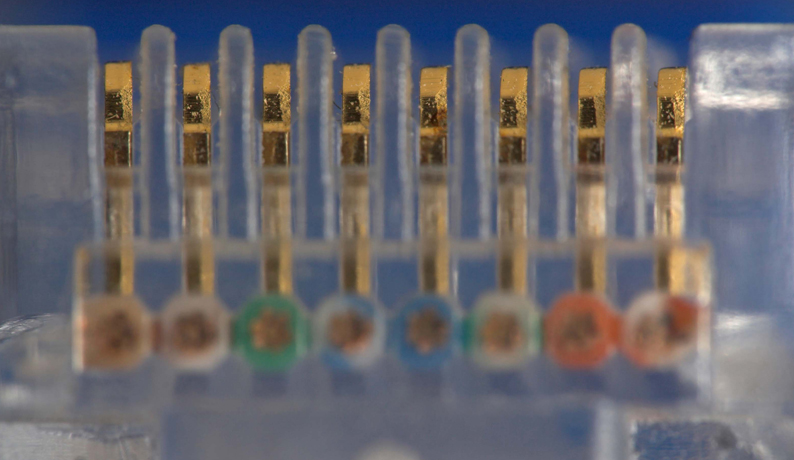

Feedthrough potting

Electronic connectors and cable assemblies are used for communications and data transfer applications as well as for power connections. The…

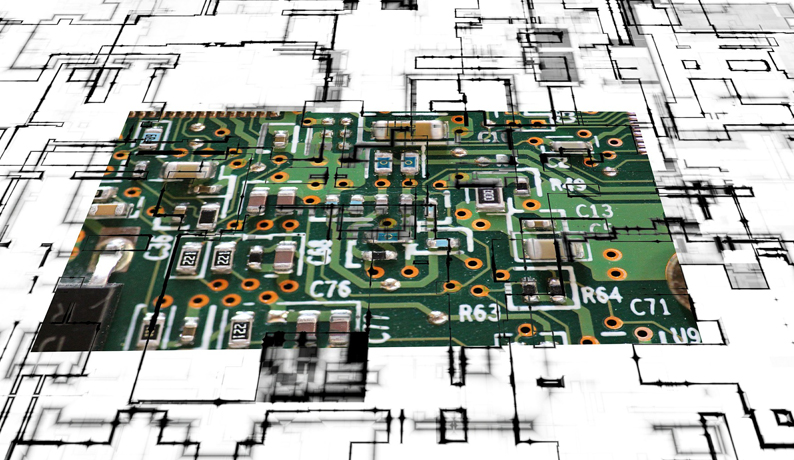

Desmear

Plasma desmear and etch-back by plasma is an established practice in the PCB industry. Drilling vias through multilayer PCB’s leaves residue, or smear, on the via walls.

Anisotropic conductive film

Plasma is used to promote the adhesion of anisotropic conductive film in flat panel display manufacture An LDI chip is…

Carbon Ash

Metallization of through-vias is often impeded by carbonaceous deposits formed during laser drilling. To remove these deposits from vias, the printed circuit boards are immersed into gas plasma

Adhesion promotion

Improve adhesive bond properties of materials. Plasma is ideal for treating plastics, metals, ceramics, and glass prior to adhesive bonding. In each case, loose boundary…