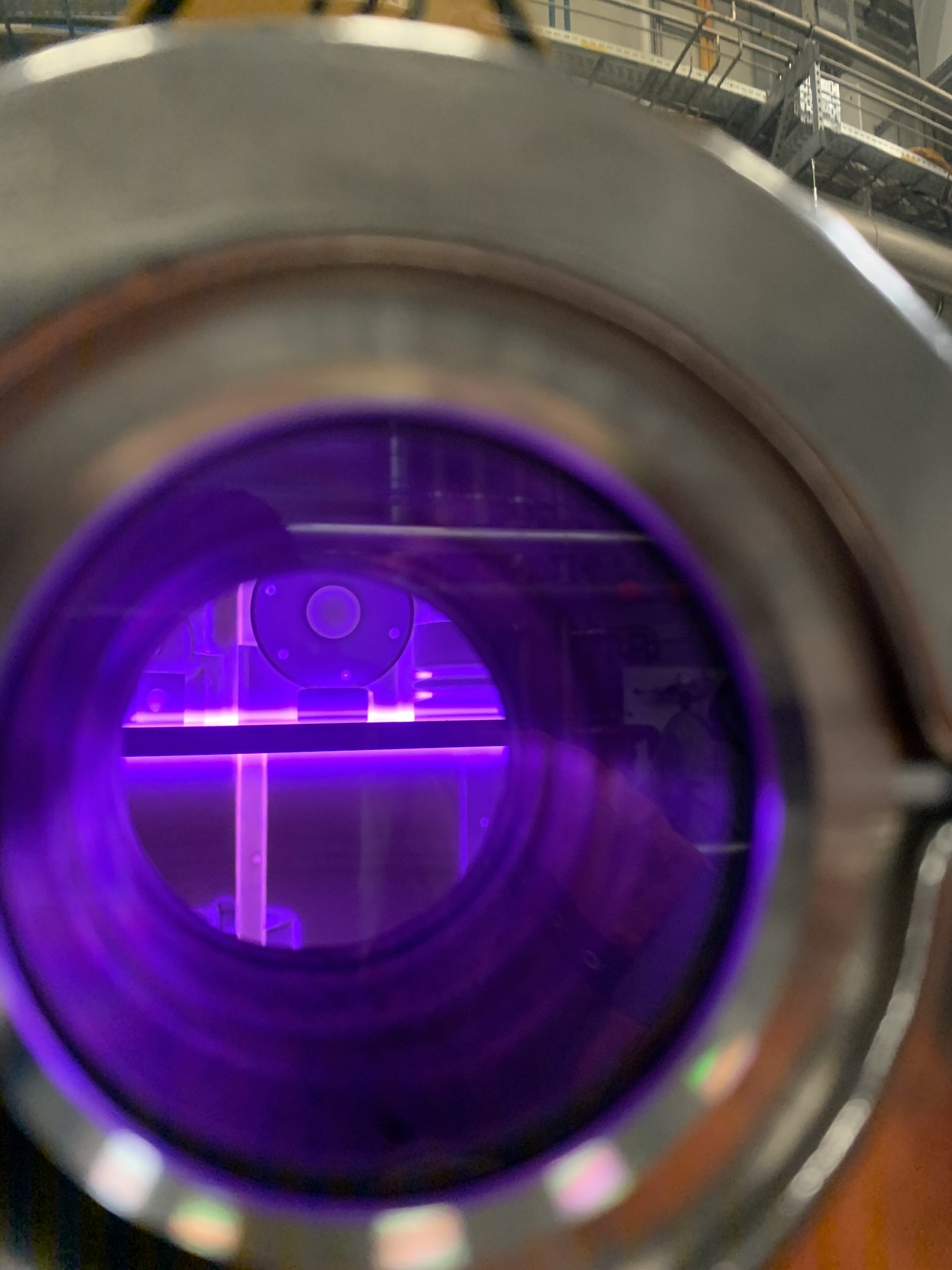

Plasma Nitriding

Nitriding in general is a heat treating that is used to case harden surfaces using nitrogen. This process is mostly used on materials such as low-carbon, low-alloy steels and other medium and high carbon steels. Products produced from this process include gears, crankshaft, molds, forging tools and dies.

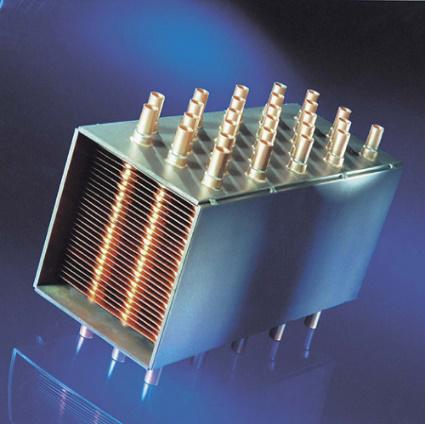

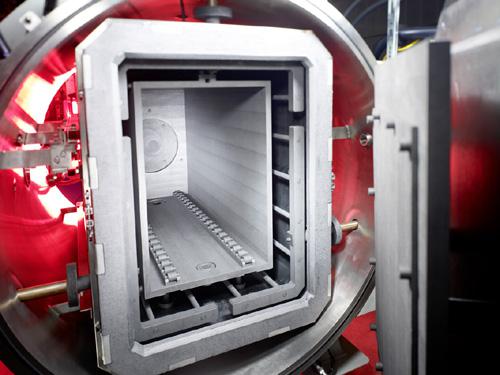

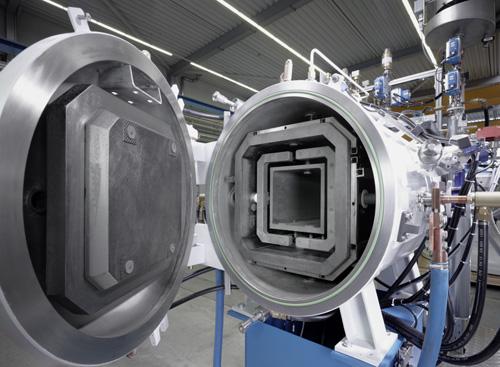

Vacuum Brazing Furnace

Vacuum Furnace technology: Graphite Heated, Metallic Heated A Vacuum brazing furnace produces stronger and longer lasting joints that are leak…

Casting

Vacuum Furnace Technology: Casting Furnaces. PVA TePla has an economic solution for the inductive melting of materials under vacuum protective…

Degassing and Cleaning

Vacuum Furnace Technology: Graphite and Metallic heated furnace, Hot Press Furnace PVA TePla’s vacuum heat furnaces can remove gases from…

Diffusion Bonding

Diffusion Bonding: Resistance Heated High Vacuum Treatment Furnace With Integrated Pressing Unit In terms of furnace technology, these are based…

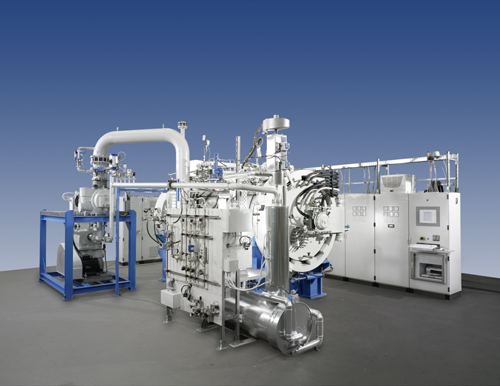

Vacuum Heat Treating System

Heating and cooling solid metal and alloy in a vacuum heat treating system creates certain desired conditions or mechanical properties….

Plasma Carburizing

Plasma carburizing is environmentally friendly and can treat your material, such as wear and corrosion resistance, hardness and load-bearing capacity…

Annealing Furnace

Vacuum furnace technology: Metal Heated (MOV) PVA Tepla America’s Furnaces provide the best treatment for making your material with the…

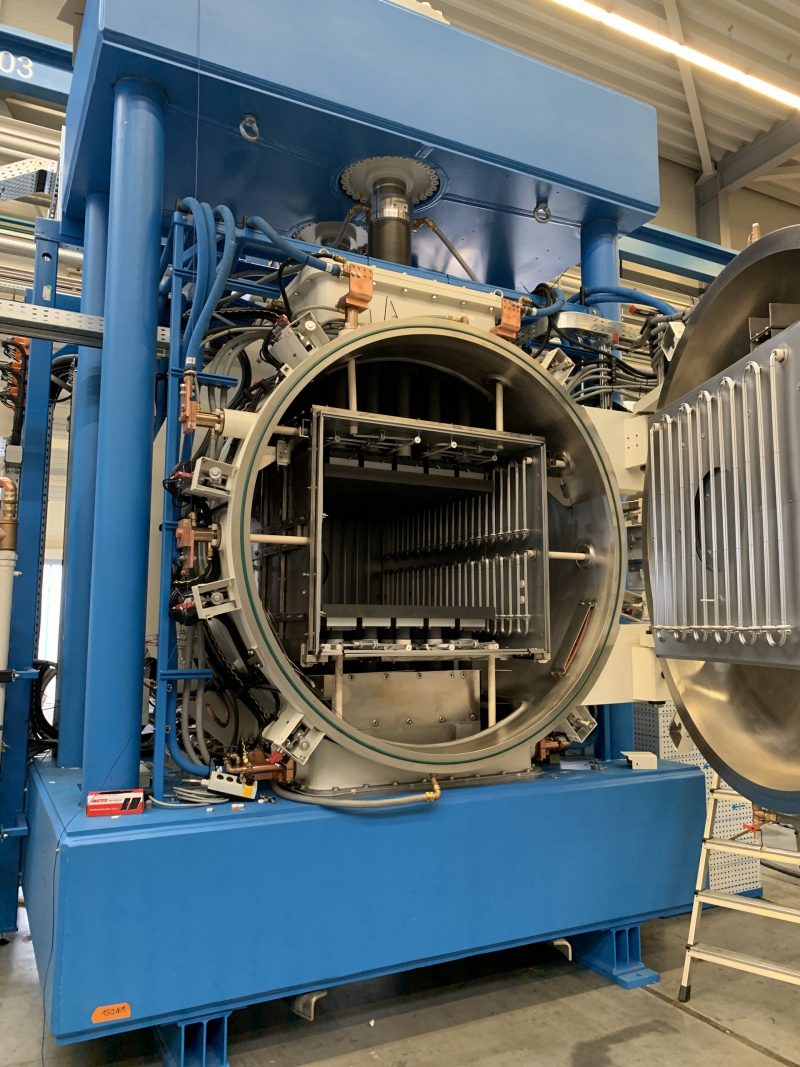

Sinter HIP furnace

The Sinter HIP furnace (Hot Isostatic Pressing) is our economical system with the same sinter capability. The Sinter HIP also…

Vacuum Sintering

Vacuum Sintering is the process of compacting and forming a solid mass of material by heat and/or pressure without melting…

Vacuum Dryer System

Industrial Vacuum Heat Dryer System from PVA TePla America can be configured to use Hydrogen for drying applications PVA vacuum…