SAM utilizes ultrasound to non-destructively examine internal structures, interfaces and surfaces of a substrate. The resulting acoustic image is analyzed to to detect and characterize features such as cracks, and voids.

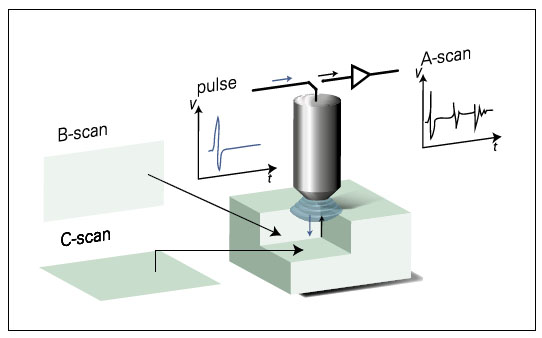

SAM operates using the pulse reflection method. The transducer is the acoustic objective-centrepiece of the microscope. The transducer produces, transmits and receives short sound pulses. The acoustic lens converts high frequency electromagnetic oscillations into a mechanical wave which propagates as a plane parallel wave field inside the lens. The cavity focuses the sound field on the sample through the coupling medium (water, IPO, inert liquid). In the sample, the sound gets reflected on material interfaces according to the mismatch in acoustic impedance. The acoustic lens receives the sound pulses reflected from the sample. The transducer transforms the sound pulses back into electromagnetic pulses which are recorded as a function of time (A-scans). Analysis of an A-scan results in a pixel with defined gray values. To produce an image the acoustic objective scans the sample point by point and line by line.