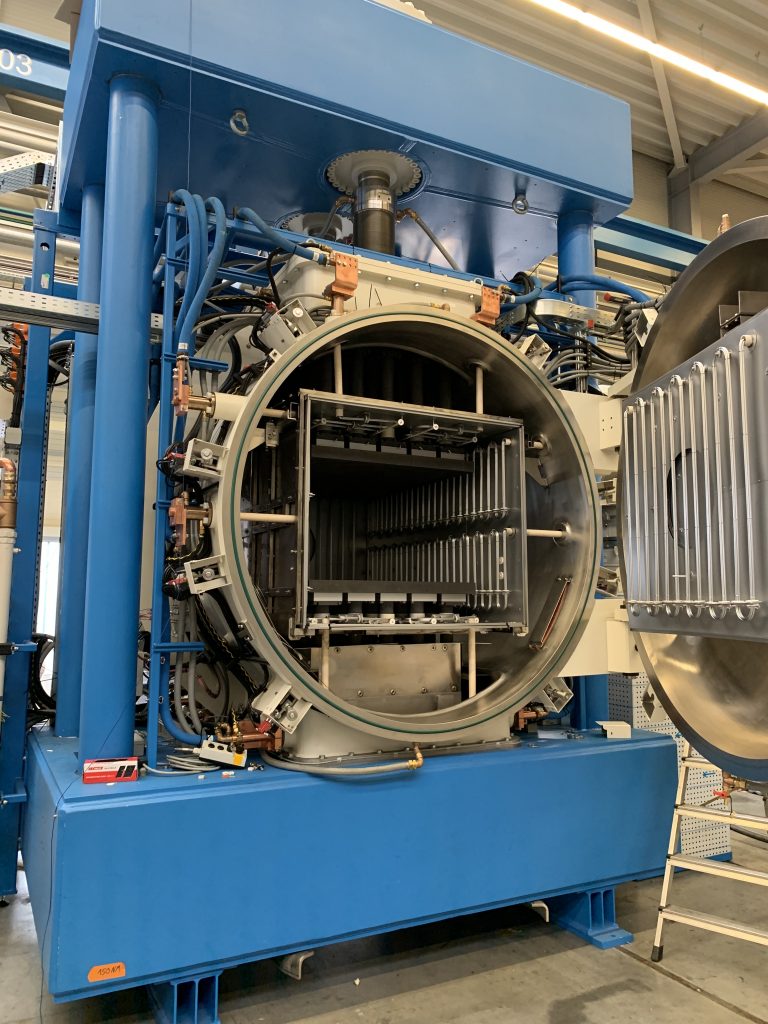

In terms of furnace technology, these are based on the PVA brazing furnaces and are also fitted with a hydraulic pressing unit. Depending on the system size, pressing forces of up to 600 metric tons can be applied to the components to be bonded. A special multi-stamp system made from high-strength materials with good thermal stability ensures that forces are distributed homogeneously, even in the case of large components with mating surfaces in excess of 1 m2. High-precision measurement sensors guarantee reproducible bonding conditions, thereby enabling this technology to be used in series production processes as well.

For more information click here

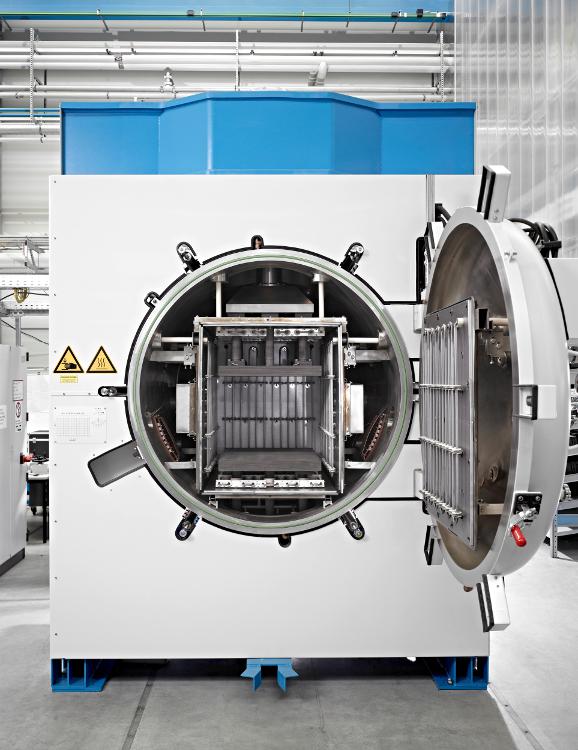

Vacuum Furnace Technology: Hot Press Furnace

High vacuum heat treatment furnaces with integrated pressing unit and power-regulated resistance heater elements. Used for diffusion bonding and forming processes under high vacuum conditions as well universal use for thermal treatments and processes where particularly demanding requirements and sophisticated materials are involved.

MOV-HP systems for diffusion bonding are cold-wall furnaces with an integrated pressing unit. The vessel is made of stainless steel, double walled and water cooled. Materials are heated in a resistance heated chamber whereby the heat transfer takes place directly via heat radiation from the heater to the thermal treatment product. The installation of pressing plates and punch can be effected both metallically and with graphite. Thermal insulation is provided by metal sheets and multi-layer foils.